Spiral Wound Gasket

Spiral wound gasket is suitable for sealing spots where the alteration of temperature and pressure are frequent. It is widely used in pipe, valve, pump, thermal, exchanger, condensing tower, plain hole and man hole of flange, etc.

| Product Name | spiral wound gasket ss321 ss304 graphite spiral winding gasket |

| Size | 10-3000mm |

| Hoop material | 304,316,316L,Mon400,Inconel,Etc. |

| spiral Wound gasket coefficient | m=2.5-4 |

| Use pressure | ≤25MPa |

| Use temperature of spiral wound gasket | -196 C -700 C (not more than 600 C in oxidizing medium) |

| Minimum pretension ratio | Y=68MPa |

| Flanges standard | ASME B16.20 |

| Type,Flange | 1.Basic type: Tongue and Groove |

| 2.With outer ring: Raised face and Flat face | |

| 3.With inner ring: Male and Female | |

| 4.With inner and outer ring: Raised face and Flat face |

Spiral wound gasket filling material:

| Filling | Steel band | Inner ring | Outer ring | Temperature(°C) | Max operating pressure(kg/cm2) |

| SUS 304 | Carbon steel | Carbon steel | -200~550 | 250 | |

| Graphite wrapping | SUS 316 | SUS 304 | SUS 304 | -150~450 | 100 |

| Teflon wrapping | SUS 316L | SUS 316 | SUS 316 | 240~260 | 100 |

| SUS 316L | SUS 316L |

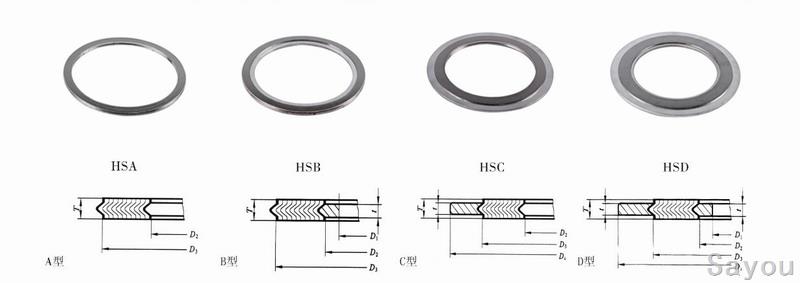

Product Structure Diagram

| Material | Lower Limit | Upper Limit | Abbreviation | ||||

| ℃ | °F | ℃ | °F | ||||

| 304 Stainless Steel | -195 | -320 | 760 | 1400 | 304 | ||

| 304L Stainless Steel | -196 | -320 | 800 | 1500 | 304L | ||

| 316 Stainless Steel | -100 | -150 | 871 | 1600 | 316 | ||

| 316L Stainless Steel | -100 | -150 | 871 | 1600 | 316L | ||

| 321 Stainless Steel | -195 | -320 | 816 | 1500 | 321 | ||

| 310 Stainless Steel | -195 | -320 | 920 | 1700 | 310 | ||

| 347 Stainless Steel | -195 | -320 | 850 | 1600 | 347 | ||

| Carbon Steel | -40 | -40 | 540 | 1000 | CRS | ||

| 20Cb-3(Alloy 20) | -185 | -300 | 760 | 1400 | A-20 | ||

| Hastelloy B2 | -185 | -300 | 1090 | 2000 | HAST B | ||

| Hastelloy C276 | -185 | -300 | 1090 | 2000 | HAST C | ||

| Incoloy 800 | -100 | -150 | 870 | 1600 | IN 800 | ||

| Inconel 600 | -100 | -150 | 1090 | 2000 | INC 600 | ||

| Inconel x 750 | -100 | -150 | 1090 | 2000 | INX | ||

| Monel 400 | -150 | -238 | 820 | 1500 | MON | ||

| Nickel 200 | -195 | -320 | 760 | 1400 | NI | ||

| Titanium | -195 | -320 | 1090 | 2000 | TI | ||

| Ceramic | -212 | -415 | 1090 | 2000 | CER | ||

| Fllexible Graphite | -212 | -415 | 510 | 950 | F.G. | ||

| PTFE | -180 | -292 | 260 | 500 | PTFE | ||

| Mica Graphite | -212 | -415 | 345 | 653 | VC | ||

| Asbestos | -240 | -465 | 500 | 932 | ASB | ||

1.Due to the role of the inner ring, played a role in blocking the media to erode the sealing surface,and the outer ring has played a role in strengthening the positioning,is a high-performance sealin products.

2.Have good compression and resilience;

3.With appropriate plasticity, can be tightened to adapt to the sealing surface of the rugged and fill the sealing surface gap to ensure that the system temperature and pressure in the case of alternating with good sealing performance.

4.Has excellent corrosion resistance; in some extreme media is not destroyed, does not produce a large expansion and contraction.

5.High temperature conditions do not soften, no creep; low temperature conditions do not harden,do not shrink.

6.There is the role of inner and outer rings, so that in the course of use, under high pressure, not blown out.In the extreme medium is not easy to be corroded, life expectancy increased and extended.Economic security, convenient and quick.It is the best choice for high temperature, high pressure.

1.Have good compression and resilience;

2.With appropriate plasticity, can be tightened to adapt to the sealing surface of the rugged and fill the sealing surface gap to ensure that the system temperature and pressure in the case of alternating with good sealing performance.

3.Has excellent corrosion resistance; in some extreme media is not destroyed, does not produce a large expansion and contraction.

4.High temperature conditions do not soften, no creep; low temperature conditions do not harden, do not shrink.

5.Have sufficient strength, under external load conditions, not crushed; under high pressure, not blown out.

1.Pre-press forming metal corrugated belt and non-metal belt alternately overlap,spiral wound made. Also according to the conditions required to add reinforced ring.

2.Because of the following advantages: the multi-channel seal,high temperature and high pressure resistance,corrosion resistance,sealing surface roughness requirements are not high on flange,etc.

3.Widely used in the flange joints, manholes, hand holes, pipes, boilers, heat exchangers, pressure vessels, steam turbines, connecting pipes, high ducts, compressors, valves and other joints of the seal.

4. Used in the field of electric power petrochemical, chemical, chemical, polysilicon, aviation, navigation, automobile, shipbuilding, food, medicine and other fields.

PREV:Bolt and nut

NEXT:NO

{{ title }}

{{ description }}